- PRODUCT SPECIFICATIONS

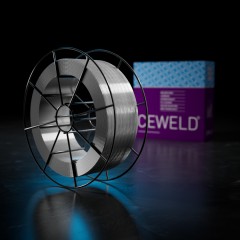

- PACKAGING

CEWELD® NiCro 625 is developed for welding and cladding nickel-based alloys such as alloy 625 or similar materials. This alloy can also be used for welding dissimilar nickel-based alloys to each other, to alloyed steels or to stainless steels and for joining 6% molybdenum super austenitic steels. Alloy 625 is most commonly used in the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts. Also used in the aerospace industry for thrust reverser assemblies, fuel nozzles, after-burners and combustion systems.

CEWELD® NiCro 625 is developed for welding and cladding nickel-based alloys such as alloy 625 or similar materials. This alloy can also be used for welding dissimilar nickel-based alloys to each other, to alloyed steels or to stainless steels and for joining 6% molybdenum super austenitic steels. Alloy 625 is most commonly used in the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts. Also used in the aerospace industry for thrust reverser assemblies, fuel nozzles, after-burners and combustion systems.

CEWELD® Nicro 625 is a solid drawn wire that is cleaned in a very special way to obtain cleaner and higher quality welds, especially when used for the Hotwire Tig process intermediate cleaning between the layers can be skipped and results in a bright seam with excellent ductility. The cast and helix of this wire are kept above the EN standards to offer excellent wire feeding and a wire that comes straight out of the torch.

Ni 6625 / NiCr22Mo9Nb / 2.4831

W.Nr: 1.4529, 1.4539, 1.4547, 1.4876, 1.4958, 1.5656, 2.4660, 2.4816, 2.4856, 2.4858,

X1CrNiMoCuN20-18-7 - X10NiCrAlTi32-20 - X5NiCrAITi31-20 - NiCr15Fe - NiCr22Mo9Nb - NiCr21Mo - X1NiCrMoCuN25 20 6 - X1NiCrMoCuN25 20 5 - NiCr21Mo - 8XNi9

ASTM: A 533 Gr1

UNS: S31254 - N08800 - N08810 - N06600 - N06625 - N08825 - N08926 - N08020

Alloy 254 SMO - Alloy 800 - Alloy 800H - Alloy 600 - Alloy 625 - Alloy 825 - Sanicro 28

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness | |

|---|---|---|---|---|---|---|

| -20°C | -196°C | |||||

| As Welded | 460 | 750 | 32 | 110 | 70 | HRc |

| Packaging | KG/unit | EanCode |

|---|---|---|