- PRODUCT SPECIFICATIONS

- PACKAGING

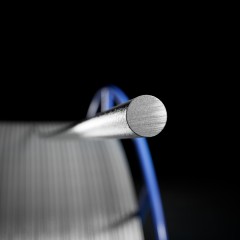

CEWELD 309LSi is for buffer layers before hard facing, dissimilar joints between ferritic and austenitic steels and or difficult to weld steels.

CEWELD 309LSi is for buffer layers before hard facing, dissimilar joints between ferritic and austenitic steels and or difficult to weld steels.

High mechanical properties and very good weldability due to a ingreased silicon content, suitable for operating temperatures from -120°C up to 300°C.

ISO 15608: 8.1 Austenit ≤ 19 % Cr , TÜV 1000: Gr. 21-30, 23% Cr, 12%Ni Type

ISO 15608: Gr. 8.1 mix 1.1

1.2780, 1.4541, 1.4550, 1.4710, 1.4712, 1.4713, 1.4724, 1.4729, 1.4740, 1.4741, 1.4742, 1.4746, 1.4762, 1.4745, 1.4825, 1.4826, 1.4828, 1.4832, 1.4878,

X15CrNiSi20 12, G-X 40 CrNiSi20 9,

AISI 446, AISI442, AISI309,

UNS S30900, S44200, S44600

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness | |

|---|---|---|---|---|---|---|

| RT | -110°C | |||||

| As Welded | 440 | 600 | 37 | 160 | 90 | HRc |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663413857 |

| D-100 | 1 | 8720663413864 |

| D-200 | 5 | 8720663413871 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663413888 |

| D-200 | 5 | 8720663413932 |

| Drum | 250 | 8720663413895 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663413901 |

| D-200 | 5 | 8720663413918 |

| Drum | 250 | 8720663413925 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663413956 |